FRUTIGER is presenting a world first at Bauma 2019

March 13, 2019In 1995, FRUTIGER launched MobyDick Quick, the world’s first wheel wash system that meant that vehicles no longer had to stop for the wheels to be cleaned. This innovation revolutionised wheel cleaning for construction vehicles and, at the same time, marked the start of FRUTIGER’s reign as the world market leader in the field of wheel wash systems. At this year’s Bauma, the Swiss company will present a world first from the field of dust control.

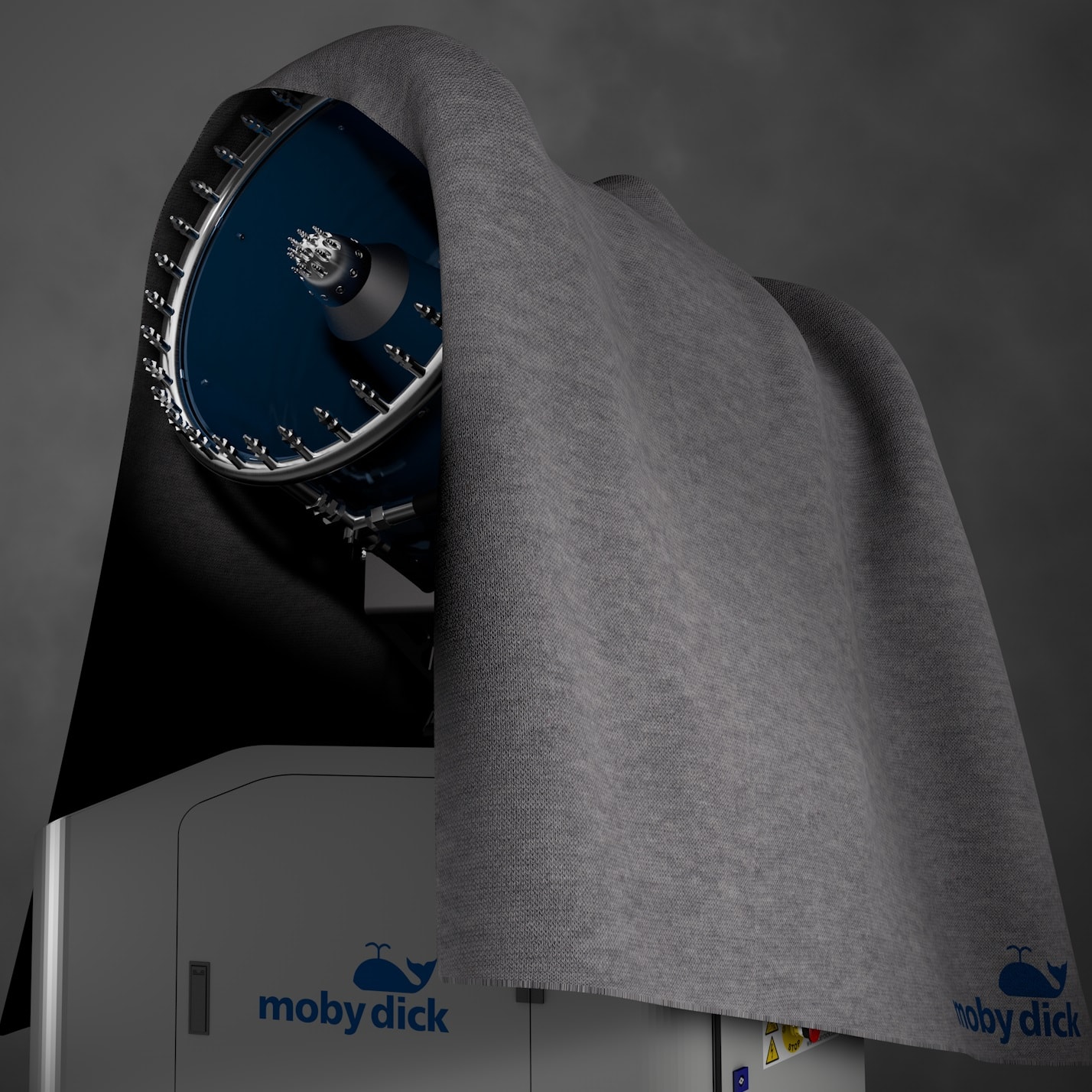

In parallel with the increasingly stringent regulations on air pollution control, as well as new findings about the harmful effects of dust on the human body, the demand for effective dust binding solutions has increased significantly. Some dust emissions, such as dust whirled up at construction site exits, have already been successfully reduced in the past using a wheel wash system. However, some dust problems, such as those typically seen in the field of demolition, as well as at steel and cement works or material terminals, increasingly required additional solutions. For this reason, FRUTIGER launched the MobyDick Cannon Line around five years ago. This robust dust control equipment has since quickly established itself on the market all over the world and is indispensable in some fields. The choice of the correct model is generally based on the nature of the dust problems encountered in the relevant type of work and prevailing weather conditions (wind, temperatures, air humidity etc.). However, these factors tend to vary considerably during use, which means that the original choice of model is no longer ideal for the new conditions. As a worst case scenario, this may even make it necessary to disconnect or swap the machine. From a long-term perspective, this situation is not satisfactory and, for FRUTIGER, it formed the basis of the development of a whole new generation of dust binding equipment under the brand MobyDick.

Cooperation with the Zurich University of Applied Sciences (ZHAW)

The first stage of development was based on intensive cooperation with the Aviation Centre at the Zurich University of Applied Sciences (ZHAW). During this stage, measurements were taken to assess the effectiveness of various items of dust binding equipment in accordance with scientific criteria. Following this, the engineers developed a total new version of the outer cone with the help of computer-aided calculations. In addition, the guiding plates were replaced by modelled high-performance stators and the motor unit was given an aerodynamic cover. After FRUTIGER had produced the first prototypes, control measurements were taken, which confirmed an increase in effectiveness of around 25% in comparison with the previous models. “The initial calculations revealed how performance can be improved at any early stage. However, even we’re surprised that the effectiveness of the FRUTIGER prototype was now so far over and above the results achieved by all the other equipment we tested” commented Michael Ammann, Research Assistant at ZHAW, about his findings. His supervisor, Professor Dr. Manfriani, added: “Our key focus involved optimising the motor performance of the fan as much as possible using current scientific knowledge in order to achieve an improved range of throw for water droplets. As a renowned university, we’re pleased to have been able to support this development using current fluid mechanics knowledge.” As conventional sheet metal is not suitable to produce an optimal aerodynamic cone formation (reflexed airfoil profile), FRUTIGER manufactured this from high-quality composite fibre. This robust material has additional benefits for everyday use, as it is very durable, extraordinarily resistant against acid and corrosion, sound absorbent and easy to repair.

The FRUTIGER engineers based at the Swiss headquarters were also working hard to ensure that the range of throw provided by dust binding equipment was continuously adjustable for the first time ever. For the New Generation 3060 model, this range varies between 30 and 60 metres and the larger 3090 model has an even bigger range of between 30 and 90 metres. “This innovation has significant added value in practice as sources of dust can now be managed from the perfect distance with maximum effect, thus drastically reducing unnecessary water loss” explains André Perret, Division Manager for Dust Binding. He adds: “Our equipment is very often used in different locations and under varying conditions. This means it’s not always ideal to run the equipment at full capacity. Therefore, our new models can be continuously regulated, which also significantly reduces electricity consumption and noise emissions for many uses”. The adjustable range of droplet throw is another advantage of these machines. This means that, on the one hand, very large areas can be covered with fine clouds of water droplets using the traditional nozzle ring, whereas, on the other hand, the inside nozzle head allows a concentrated flow of droplets to be produced, which is less susceptible to wind. The quantity of water used can also be regulated and, like the range of throw and type of spray, it can be perfectly adapted to the prevailing working conditions. Urs Frutiger, CEO of the FRUTIGER group, says of the new development: “By collaborating with ZHAW and conducting comprehensive testing, we’ve optimised a technology that originated from the snow industry for use in the building industry. This provides our customers with real added value in their everyday work compared with using converted snow cannons. It’s definitely an advantage that we’ve been working in the building sector for over 60 years and develop our equipment specially for use in dust binding right from the outset”. This has even won over the Agency for Innovation of the Swiss Confederation, which also supported the development of this new technology.

MobyDick Dust Control Cannon

The right solution for every problem

FRUTIGER also has good news from the field of wheel wash systems: the MobyDick ONE, presented at Bauma 2016, has since been used on numerous sites by prestigious building firms. The functionality, quality and wash performance of this unique piece of equipment has even been winning over customers who expect the very best from their wheel wash systems over the past three years. What began with the launch of ONE in 2016 will be concluded at Bauma 2019: The restructuring of the MobyDick wheel washing system product range. The range now includes around 30 standard models in the ConLine KIT Flex and KIT Plus lines, which are predominantly used on building sites. In addition, the lines ONE and RS Line offer tailor-made solutions to meet the highest standards and are perfect for use in one location over a number of years. FRUTIGER’S truly unique product range and ISO-certified production plants guarantee tried and tested solutions for all circumstances, as well as excellent value for money.

MobyDick ONE 720

Cost advantages thanks to automatic pre-cleaning

Even the demucking sector, where the main focus is not clean roads, but rather pre-cleaning civilian and military vehicles, has developed significantly over the past years. Increasing numbers of operators of large vehicle fleets recognise the cost advantages associated with using a MobyDick device to pre-clean very dirty wheels, chains and chassis, right up to a CAT D12. Spending hours cleaning using a spray lance is already a thing of the past at many modern sites. Recently, for example, the operator of a large disposal site in the US state of Virginia recognised the changing times and invested in the advantages offered by modern demucking equipment by FRUTIGER.

MobyDick Demucking System

FRUTIGER in exhibition hall B5

FRUTIGER is excited to present all its innovations at Bauma in exhibition hall B5 at stand 224. MobyDick specialists from all over the world will be there for the entire week and will always be available for interesting conversations. Visit our new website www.mobydick.com to find out more.