Wheel Wash

Wheel wash system - Clean public roads

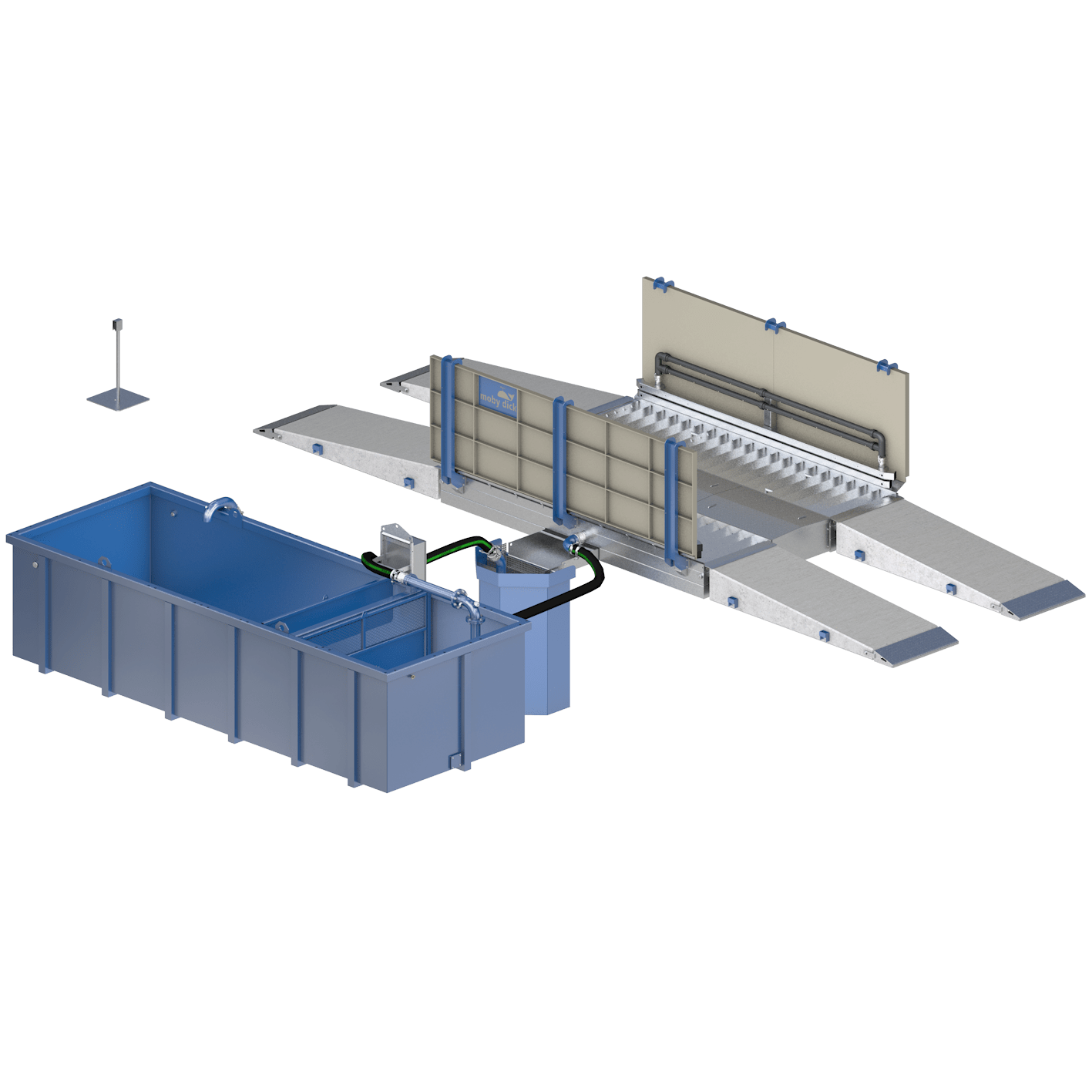

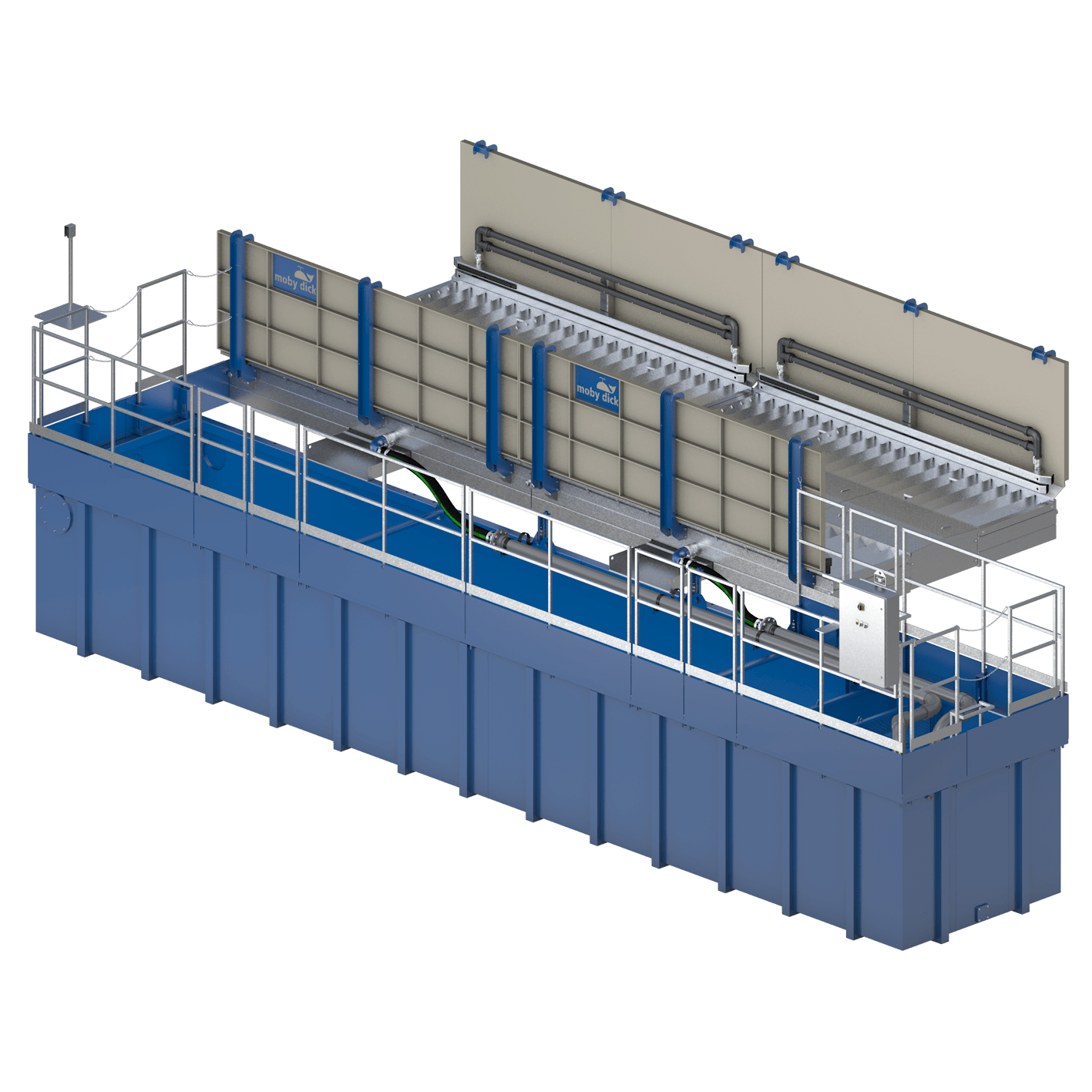

For over three decades, the Moby-Dick brand has been the symbol of performance, first-class quality, and global leadership in emission control. The wheel washing systems division comprises the modular models of the Construction Line (ConLine) and the TailorMade Line for customers who prefer a custom-made wheel wash system.

Good to know:

Thanks to cutting-edge technology and the most extensive range of products on the market, our specialists can solve almost any problem related to soiled public roads.

Our product lines

Clean roads with FRUTIGER Wheel Washing Systems

Discover leading Wheel Wash solutions by FRUTIGER, powered by advanced MobyDick technology. With over 4,000 systems installed worldwide, we are pioneers in developing efficient and user-friendly Wheel Washing solutions for optimal wheel and vehicle cleaning. Our Wheel Wash systems, including roller wash and drive-through wash stations, set new standards in performance and reliability. Our drive-through Wheel Washing stations, equipped with an innovative vehicle detection sensor, automatically trigger the washing process to ensure effective and thorough cleaning of wheels and chassis. The precisely tuned nozzle system, featuring both ground and side nozzles, ensures comprehensive cleaning with every wheel rotation, without compromising the safety and visibility of the driver by leaving higher vehicle areas like windows and rearview mirrors untouched.

Another cornerstone of our Wheel Wash systems is the eco-friendly water management system. Dirty water flows into side recycling tanks, where it is treated by robust MobyPump submersible pumps for reuse, while settled solids are efficiently removed. This sustainable practice not only reduces water consumption but also supports companies in complying with environmental standards.

Choose FRUTIGER, your reliable partner for innovative and practical solutions in emission control and vehicle care. Benefit from our expertise and the advantages of MobyDick technology to optimize your operations and minimize environmental impact.

Frequently Asked Questions (FAQ)

-

A wheel washing system automatically cleans a vehicle’s tires as it moves through the system, using recycled water to remove accumulated dirt and mud. This process prevents contaminants from being carried onto public roads, thereby maintaining cleanliness and safety.

-

There are two primary types:

- Roller Systems: The vehicle stops, placing its wheels between rollers. A start bar triggers the washing process, during which the wheels are automatically turned and cleaned by water sprayed from multiple nozzles.

- Drive-Through Systems: The vehicle drives slowly through the system, and a light barrier at the entrance triggers the washing process. Wheels and chassis are cleaned by water sprayed from numerous nozzles without the need to stop.

-

MobyDick wheel washing systems feature an eco-friendly water management system. Dirty water flows into side recycling tanks, where it’s treated by robust MobyPump submersible pumps for reuse, and settled solids are efficiently removed. This sustainable practice reduces water consumption and helps companies comply with environmental standards.

-

Key considerations include:

- Site Requirements: Assess the size and type of vehicles, the volume of traffic, and the level of contamination.

- Environmental Regulations: Ensure compliance with local environmental laws regarding water usage and discharge.

Maintenance Needs: Consider the ease of maintenance and availability of support services. - Cost: Evaluate the initial investment against long-term benefits and operational costs.

Consulting with our specialists can help tailor a solution to specific needs.

-

The installation time for a wheel washing system depends on the type of system and site conditions. Modular systems, such as drive-through models, can often be installed in a matter of days. In contrast, permanent systems requiring groundwork and custom configurations may take several weeks. MobyDick offers guidance and support to ensure efficient installation with minimal disruption to operations.

-

Regular maintenance is essential to keep a wheel washing system functioning efficiently. Key tasks include:

- Inspecting Nozzles and Pumps: Ensure proper water flow and pressure.

- Cleaning Recycling Tanks: Remove settled solids to maintain water quality.

- Checking Electrical Components: Verify that all sensors and controls are operational.

- Replacing Worn Parts: Replace brushes or other components subject to wear over time.

MobyDick provides maintenance plans and technical support to help customers extend the lifespan of their systems.